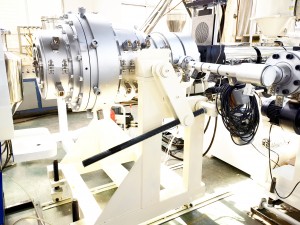

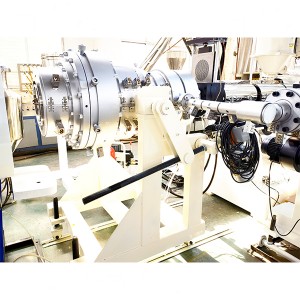

HDPE pipe extrusion making machine

HDPE pipe manufacturing machine

HDPE pipe extruder machine is mainly used for producing pipe of waster supply and drainage in the field of agriculture and sonstruction cable etc. This machine consists of vacuum calibration tank, haul off unit. Cutting unit, stacker etc. The single screw extruder and haul off unit apply famous A/C frequency conversion speed regulation device, both vacuum pup and driving motor apply famous brand. The haul-off unit includes two-claw type, three-claw type, four-claw type, six claw type, eight-claw type, ten-claw type, twelve-claw type etc. Dust free cutting machine, saw blade cutting machine or planetary cutting machine can be applied, the property of machine group is reliable.

HDPE Pipe.

■ Good hygienic performance: no heavy metal salt stabilizer is added during HDPE pipe processing, the material is non-toxic, no scaling layer, and no bacteria breeding, which solves the hidden danger of secondary pollution of urban drinking water.

■ Excellent corrosion resistance: Except for a few strong oxidants, it can withstand the erosion of a variety of chemical media; no electrochemical corrosion.

■ Long service life: HDPE pipe can be used safely for more than 50 years under rated temperature andpressure .

■ Better impact resistance: HDPE pipe has good toughness and high impact resistance, and heavy objects directly pass through the pipe, which will not cause the pipe to be broken.

HDPE pipe is simply a pipe made of polyethylene; this material gives the pipes some special features which creates benefits and these advantages have led to the popularity of polyethylene pipes.

HDPE pipes have many advantages, high quality, reliability of pipe and fittings, ease of loading and transportation of pipes and fittings of polyethylene due to their relatively low weight, quick and easy installation have made polyethylene types the best choice for various projects.

HDPE pipe have a good bending radius and have very good resistance to impact and pressure at very low temperatures. Acidic and basic environments, as well as many solutions and chemicals do not affect polyethylene. This is one of the most important advantages of a polyethylene pipe and polyethylene fittings.

Polyethylene materials used to produce polyethylene pipes are different from polyethylene materials used to produce other polyethylene products. Polyethylene is available in various grades, and each of these types of polyethylene materials is used for various applications.