Wholesale China Pvc Pipe Production Line Manufacturers Pricelist - PVC fiber reinforced pipe production line – Qiangsheng Plastic

Wholesale China Pvc Pipe Production Line Manufacturers Pricelist - PVC fiber reinforced pipe production line – Qiangsheng Plastic Detail:

Product introduction

This line consists of main extruders, water cooling tank, haul off machine, fiber braiding machine, coiler etc, which has reasonable design, unique structure, stable performance, easy operation and maintenance, constant production capacity, warmly welcomed by customers.

Different models of production lines can produce PVC pipes with different diameter.

|

Extruder Modle |

SJ45 |

SJ55 |

SJ65 |

|

Pipe Diameter(mm) |

16-32 |

16-50 |

16~75 |

|

Production Capacity(kg/h) |

40-60 |

50-70 |

60~100 |

|

Production Speed(m/min) |

6 |

7 |

10 |

|

Total Power(kw/h) |

30 |

45 |

60 |

Details introduction

1.Single screw extruder with automatic feeding device

According to the requirements of different diameters, different wall thicknesses and different output of pipes, we have many models of special twin screw extruders to choose from. It adopts a specially designed screw structure, which can evenly heat, plasticize PVC granules and extrude pipes .

(1) Motor brand: Siemens

(2) Inverter brand: ABB/Delta

(3) Contactor brand: Siemens

(4)Relay brand: Omron

(5) Breaker brand: Schneider

(6) Heating method: Ceramic or cast aluminum heating

2. Mould

The mould is made of high-quality alloy steel, the internal flow channel is chrome-plated and highly polished, which is wear-resistant and corrosion-resistant; With the special sizing sleeve, the product production speed is hight and the surface of the pipe is good.

(1) Material: 40GR

(2) Size: Customizable

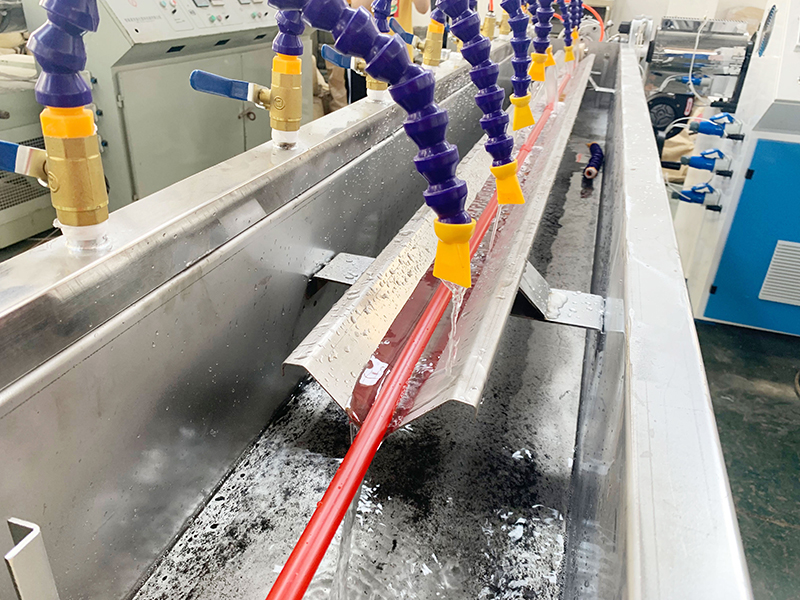

3. Stainless steel cooling tank

It can calibrate and cool the PVC pipe from the mould.

(1) Length: 2000mm

(2) Material: stainless steel

(3) Calibrating method: inside pressure

(4) Up and down, front and behind maybe moved

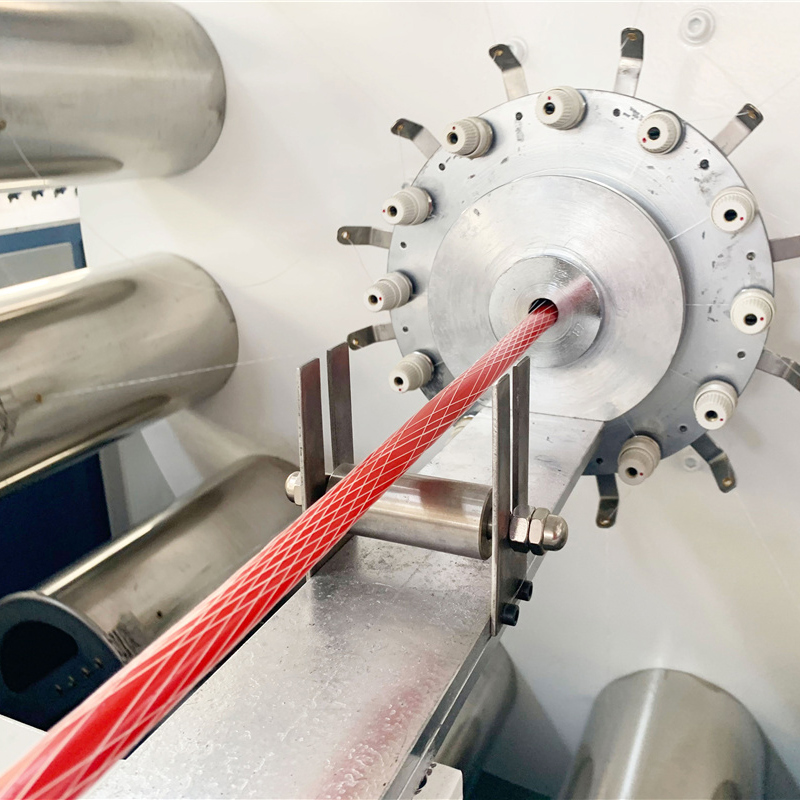

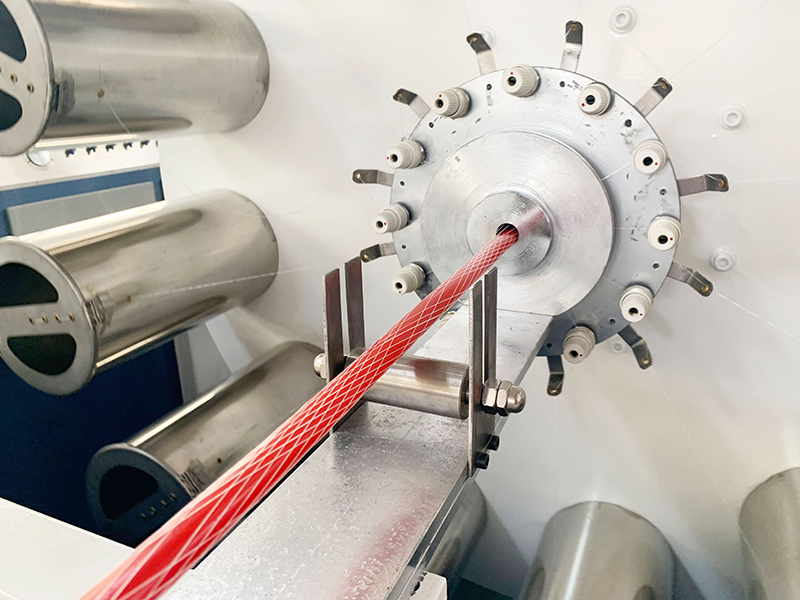

4. Knitting Machine

It is used for knitting or braiding the fiber.

(1) Power: 3 kw

(2) 32 positions for fiber

5. Haul-off machine

It is used for haul-off the PVC hose.

(1) Motor power: 0.75 kw

(2) Valid length: 600mm

(3) Haul-off speed: 0-18m/min

(4) Using good quality flat adhesive backed tape

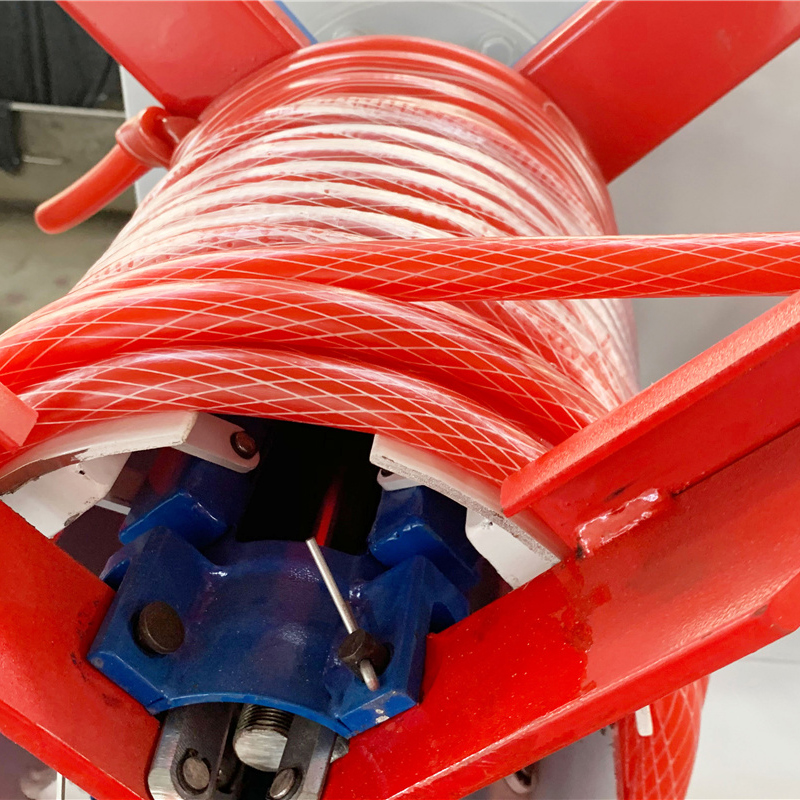

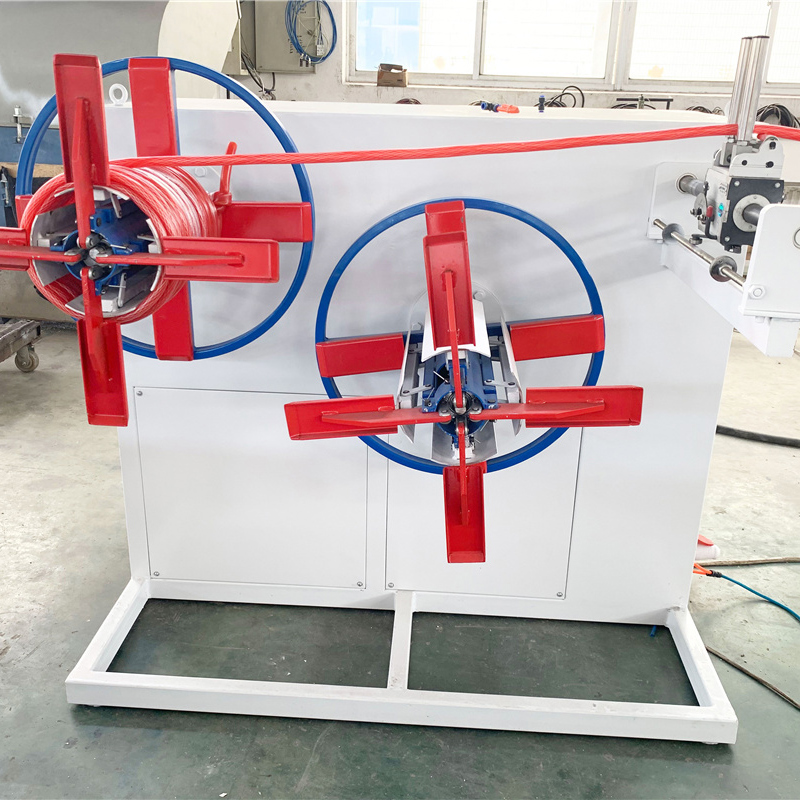

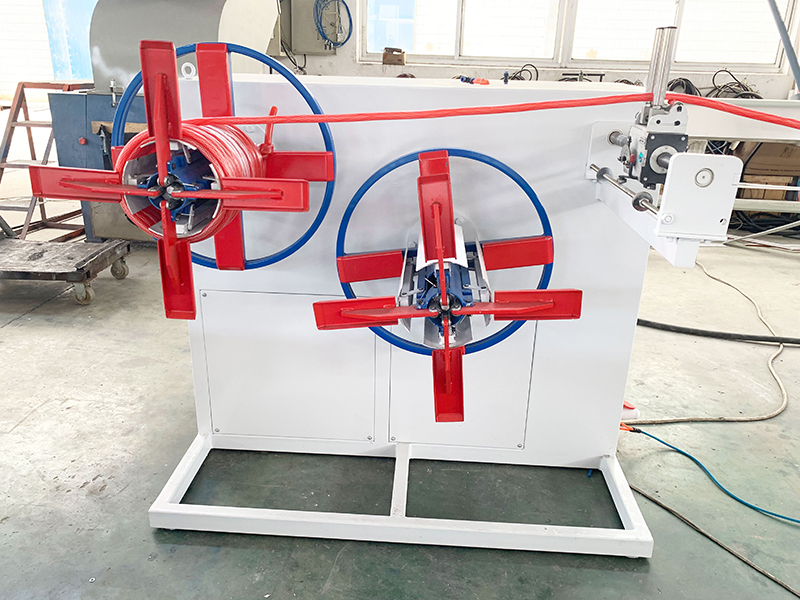

6. Winding machine

It is used to wind up PVC hoses.

(1) Length of rolling pipe: 50-100feet

(2) Using power torque and auto winding

You just tell me what machine you want, let us do the rest work:

1. Design and manufacture suitble machine for you.

2. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspect the running production line.)

3. Delivery.

4. We will provide after-sales service:

(1) Field installation and commissioning;

(2) Field training your workers; (3) Field maintenance and repair service ;

(4) Free Spare Parts ;

(5) Video/Online technical support.

Product detail pictures:

Related Product Guide:

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for Wholesale China Pvc Pipe Production Line Manufacturers Pricelist - PVC fiber reinforced pipe production line – Qiangsheng Plastic , The product will supply to all over the world, such as: Vancouver, Italy, Ghana, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to provide professional, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We will serve you with all sincerity!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.