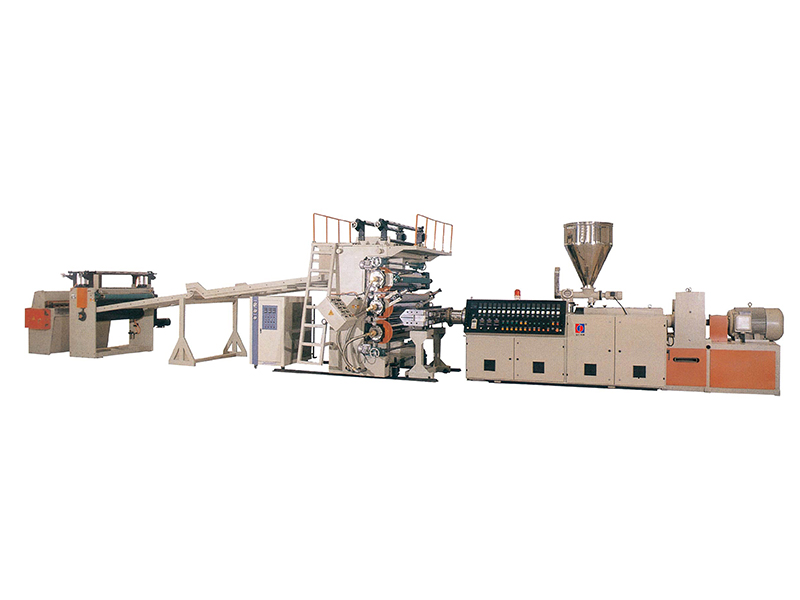

China Wholesale Pvc Pipe Extrusion Machine Line Factory Suppliers - PP PE PVC single wall corrugated pipe extrusion line – Qiangsheng Plastic

China Wholesale Pvc Pipe Extrusion Machine Line Factory Suppliers - PP PE PVC single wall corrugated pipe extrusion line – Qiangsheng Plastic Detail:

Application

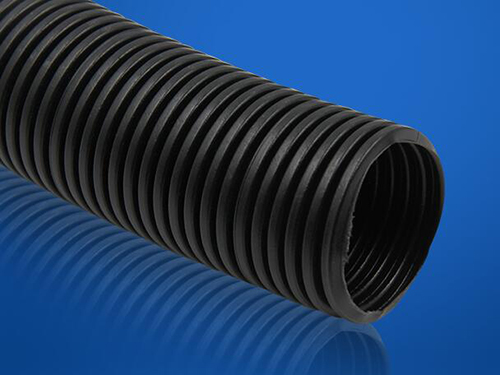

Plastic single wall corrugated pipes have features of high temperature resistance, corrosion and abrasion resiatance,high intensity and good flexibility,etc.they are widely used in fields of auto wire harness, electric thread-passing pipes,circuit of machine tool,protective pipes of lamps and lantern wires,tubes of air conditioner and washing machine,etc. Applications:plastic single wall corrugated pipe making machine can produce electrical thread-passing pipes,circuit of machine tool,protective pipe of lamps,water pipes in conditioner,washing machine, bathroom, etc.

Features

1.Extruder: high efficient screw, hard gear surface gearbox, uniformed raw material heating, good plasticization, high extrusion speed.

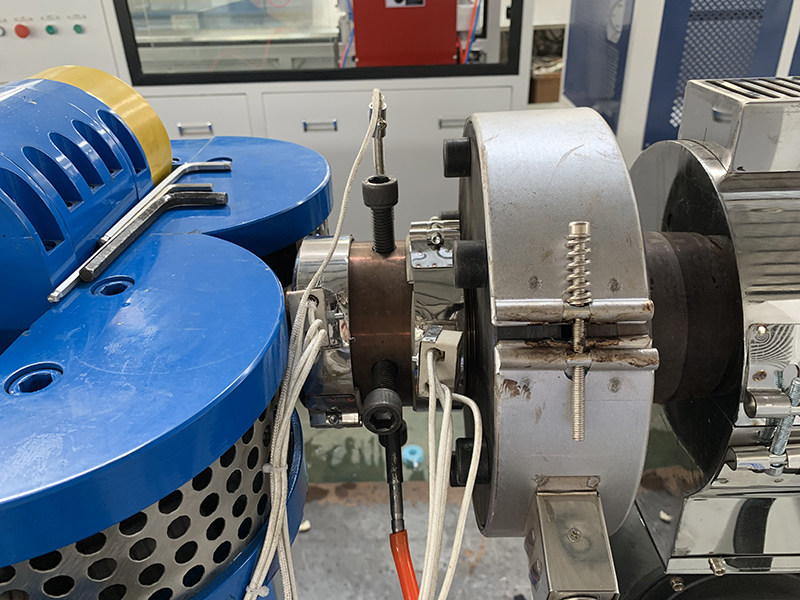

2.Corrugation forming machine: closed structure, module link in the overall closure base does round-trip running in the running tunnels.

3.Forming modules: it is made of hard steel, dealed with a rigorous use of CNC finishing materials produced to ensure the hardness and precision of the molding modules. These modules are easy and convenient to change

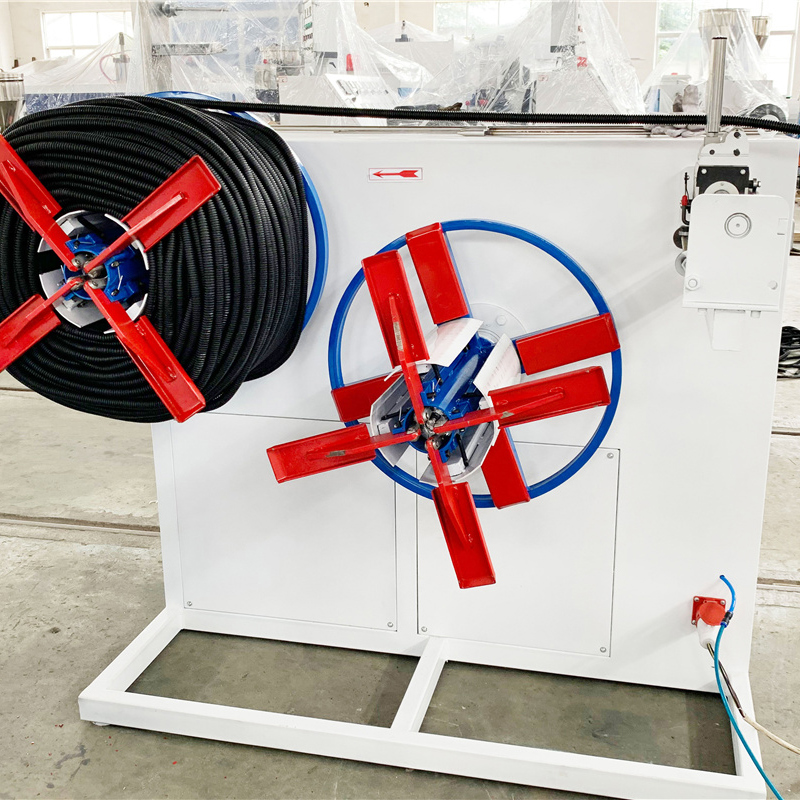

4.Coiler :Single position or double position with torque motor.

5.Electrical parts: ABB inverter, Schneider contactor, RKC thermo controllers etc.

Product Paramenters

|

Corrugated Pipe Diameter |

4.5-9 mm |

9-32mm |

16-50 mm |

|

Main Machine Model |

SJ-30 |

SJ-35 |

SJ-45 |

|

Screw L/D |

30:1 |

30:1 |

30:1 |

|

Production Capacity |

8 kg/h |

15 kg/h |

25 kg/h |

|

Main Motor |

5.5 kw |

7.5 kw |

15 kw |

|

Pair of Modules |

42 |

Depends |

Depends |

|

Production Speed |

6-10 m/min |

8-12 m/min |

8-12 m/min |

Product detail pictures:

Related Product Guide:

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for China Wholesale Pvc Pipe Extrusion Machine Line Factory Suppliers - PP PE PVC single wall corrugated pipe extrusion line – Qiangsheng Plastic , The product will supply to all over the world, such as: Gambia, Bangladesh, Liberia, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services for you. We warmly welcome you to contact us and please feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.