China Wholesale Pe Foam Sheet Machine Suppliers Factories - SPC Floor Production Line – Qiangsheng Plastic

China Wholesale Pe Foam Sheet Machine Suppliers Factories - SPC Floor Production Line – Qiangsheng Plastic Detail:

Materials

The spc lock floor is made of polyvinyl chloride (divided into pure new material, mixed material, recycled material), calcium powder (classified with stone powder grade) and solvent (the use of chemical grades also use plant solvent food grade).

Processing

Process 1: mixing

Automatic metering according to raw material ratio → hot mixing of high-speed mixer (temperature of hot mixing: 125 ℃, It is to

mix all kinds of materials evenly, remove the moisture in the materials) → enter the cold mixing (cool the materials, Prevent

caking and discoloration, cold mixing temperature: 55 ℃.) → mix evenly by cooling;

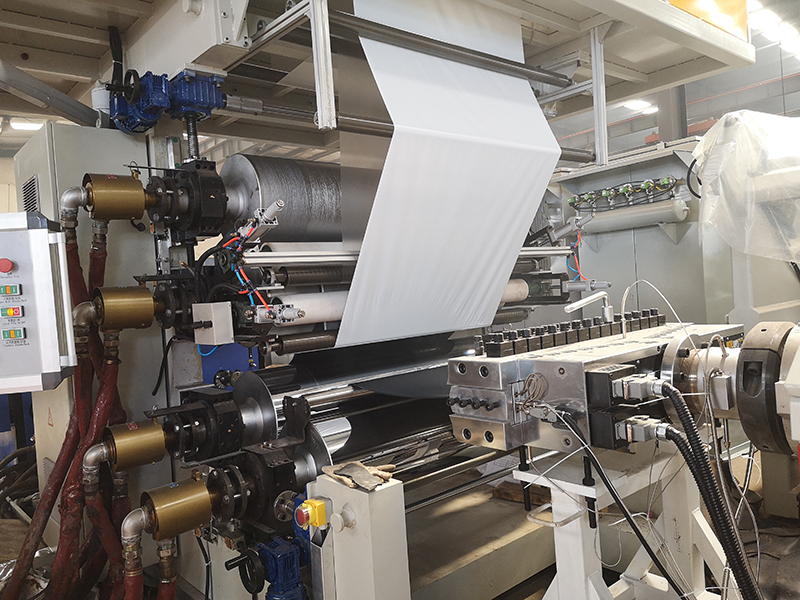

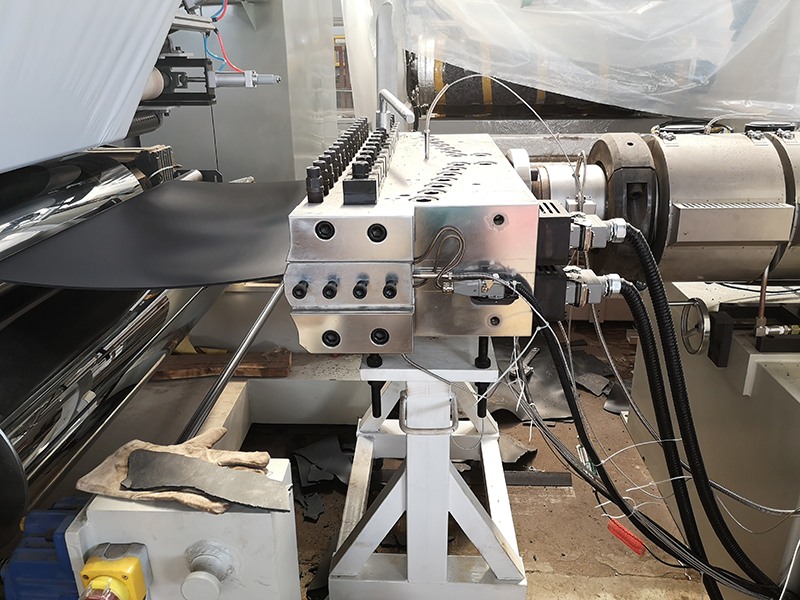

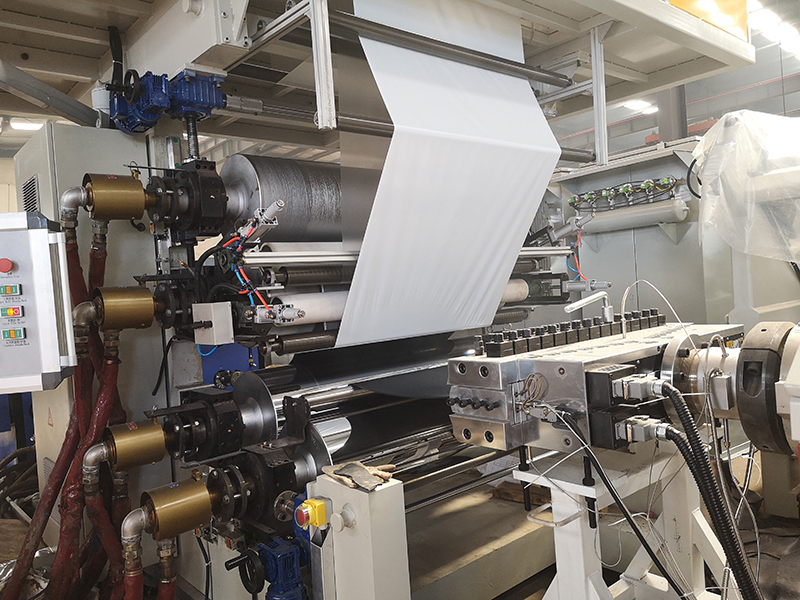

Process 2: extrusion

the twin-screw extruder for heating extrusion → enter the sheet die head for extrusion molding, forming the sheet. After four

roller calender, the base material is fixed thickness → color film → wear layer → cooling → cutting;

Process 3:UV tempering

Surface UV → tempering (tempering hot water temperature: 80 ~ 120 ℃; cold water temperature: 10 ℃)

Process 4: slitting and slotting packing

Cutting → slotting, trimming and chamfering → inspection → packaging

Machine List

Extrusion Part

| No. | Machine Name | Quantity |

| 1. | Mixing Machine For PVC and Calcium powder | 1set |

| 2. | Feeding Machine For Mixing Machine | 1set |

| 3. | Automatic Feeding Machine For Extruder | 1set |

| 4. | SJSZ 92/188 Conical Twin Screw Extruder | 1set |

| 5. | T-shaped Mould and Die | 1set |

| 6. | Four-roll Calender | 1set |

| 7. | Cooling Frame | 1set |

| 8. | Trimming Set | 1set |

| 9. | Hauling Device | 1set |

| 10. | Automatic Cutting Machine | 1set |

| 11. | Stacking Section | 1set |

Advantages:

a.zero benzene and formaldehyde,no glue and poisonous substance,and it can be 100%recycled;

b.stable perforance: no cracking, no expansion, no deformation, no maintenance and maintenance, easy to clean, save the cost of later maintenance and repair

c.Water proof and moisture proof. it can be used in an environment where traditional wood products cannot be applied;

d.fire retardant: fire rating B1 level;

e.anti-insect,termite-proof,antibacterial new flooring;

f.good sound absorption effect:upto 20dB which is suitable for places such as: hospital,library;

g. easy installation: both interlocking click lock system or dry back are ok;

h.colorful wood grain decorative film to choose from and together with embossing pattern,the SPC flooring offers a wood look also wood touching feel.

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Wholesale Pe Foam Sheet Machine Suppliers Factories - SPC Floor Production Line – Qiangsheng Plastic , The product will supply to all over the world, such as: Romania, Barcelona, Honduras, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.